Hybrid Bond

What is a hybrid grinding wheel? Hybrid grinding wheels offer the benefits of hugely reduced cycle times, with material removal rates of up to 10 times that of any resin bond product. Our unique bond system, comprising of a mixture of specially selected alloys, ceramics and diamond coatings offer the added benefit of a lower spindle load, excellent thermal stability, reduced tool deflection plus longer spindle life and less heat transfer to coolants. Our hybrid bond grinding wheels offer the benefits of superb quality and consistency, plus some of the most competitive pricing in the industry.

HYBRID BOND DIAMOND & CBN GRINDING WHEELS

For years, the round tool manufacturer had to compromise between hybrid grinding wheel life and stock removal. It has been a never-ending battle to find the best combination of cycle time and tool consistency and accuracy. These problems have been significantly reduced through the introduction of Eagle Superabrasives new hybrid bond system. Whether you are manufacturing new tools or re-sharpening, ESI’s new Pro Flute, Pro Gash or Pro O.D. wheels will get the job done in the most economical and efficient way possible.

ESI Pro Flute, Pro Gash and Pro O.D. wheels allow much higher stock removal rates for reduced cycle times while offering tremendous form holding capabilities, which means less machine down time for increased productivity and profitability.

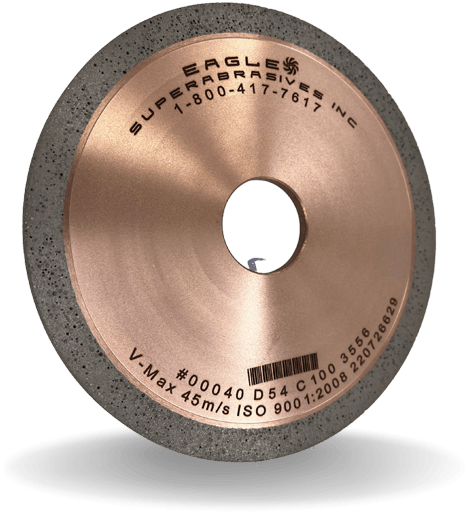

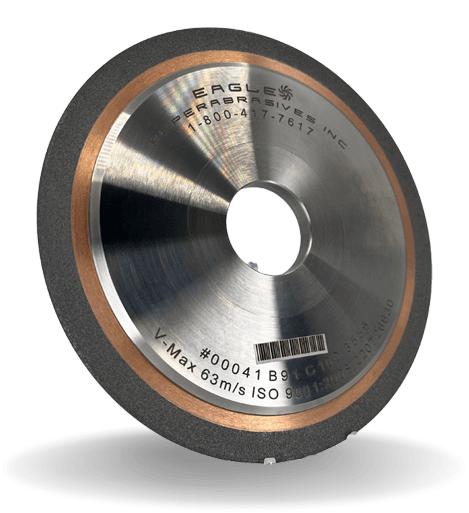

Pro-Flute Bond Diamond Wheels

Pro-Flute Hybrid Bond Diamond wheels are ultra high-performance grinding wheels that are specially designed to flute, gash and O.D. grind carbide rounds for manufacturing end mills, gun drills and other types of high-performance rotating tools. Pro-Flute wheels can produce tools at traverse rates and in-feeds that are simply impossible for resin bond wheels to match. Bottom line: Pro-Flute Hybrid grinding wheels will save your customers time and money!

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.