- 5 Horsepower minimum recommended

- High pressure coolant 100PSI+ – Filtered and Chilled coolant is recommended

- Rigid machine with spindle bearings in good condition – maximum 0.0002″ side-load runout

- A machine capable of producing tolerances required

Getting Started with Hybrid Diamond Wheels

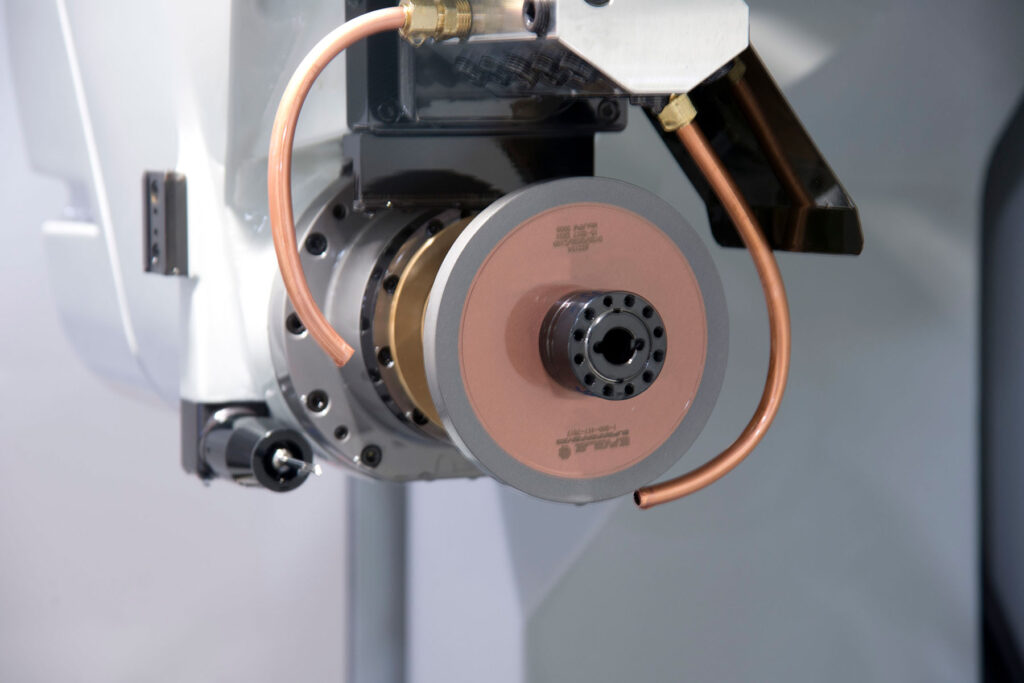

Minimum Machine Requirements for Hybrid Bond

Choose the Right Wheel for the Job

Wheel Speed

RPMs of wheel is important to ensure optimized wheel performance. Speeds below are the recommended range. Use slower speed for a freer cutting wheel, and faster speed for better form retention.

| Diamond | CBN | |

| Fluting | 16-18 m/s or 3150-3540 SFM | 20-22m/s or 3900-4425 SFM |

| Gashing | 20-30 m/s or 3900-5900 SFM | 25-38m/s or 4900-7400 SFM |

| End/OD | 25-35 m/s or 4900-6900 SFM | 31-44m/s or 6100-8650 SFM |

Depth of Cut and Feed Rate Suggestions

Every tool is different. Consider the volume of carbide being removed, as well as the surface area contact of the hybrid bond diamond wheel on the part when determining the best in-feed and traverse rates. The graph below is a guideline to use as a starting point, and is based on 1/2” tool size. For smaller tools, a faster feed rate will be needed to prevent wheel loading. For larger tools, a slower feed rate will be needed to prevent overheating or breaking of parts, or damage to the wheel. Call one of our Application Engineers for recommended Feeds and Speeds for your part today!

When you’re ready, contact us for a free quote

or call us at (828) 759-5898