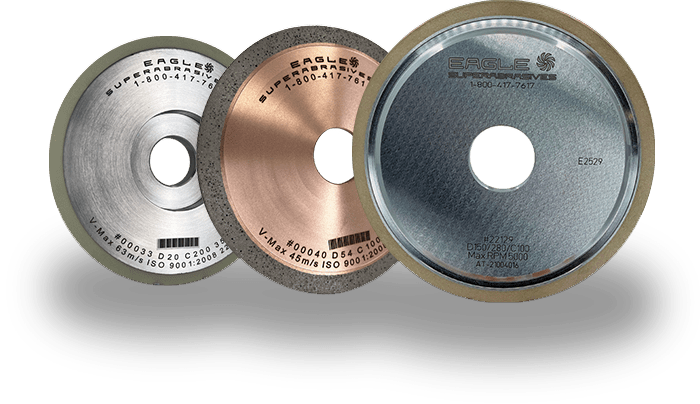

Resin Bond

Eagle Superabrasives and develops and engineers resin bond grinding wheels for use in many industries and applications Our bonds are designed to maximize and optimize your operations while providing superior performance and cost effectiveness. Resin bond is a combination of fillers and resins pressed under heat that are easily dressed to angle forms, straight forms, and special radius forms. A very fine finish can be achieved using resin bond products.

High Performance Wheels

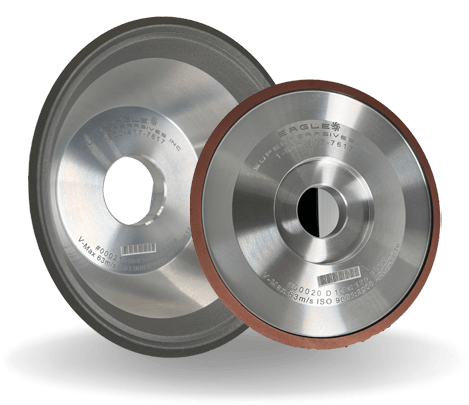

When it comes to delivering top-quality grinding wheels, we don’t compromise. Eagle offers a wide range of abrasives, bonds, and core options. From start to finish, an application engineer will be by your side.

Resin Bond Diamond & CBN Wheels

Resin bonds are the most commonly used bond system for superabrasive grinding wheels. They are used for grinding all types of tungsten carbide tools, ceramics, glass, ferrites, refractories and semi-conductors. It offers good elasticity, superior surface finish and highly efficient grinding performance, all at an affordable price.

Phenolic resins are typically used for wet or dry grinding, off-hand grinding, centerless grinding and general purpose tool room use. Polyimide resins offer a considerable performance increase over generic phenolic resins. You can expect to see greater stock removal, better form holding, higher temperature tolerance and minimal wear when grinding with polyimide bond wheels.

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.