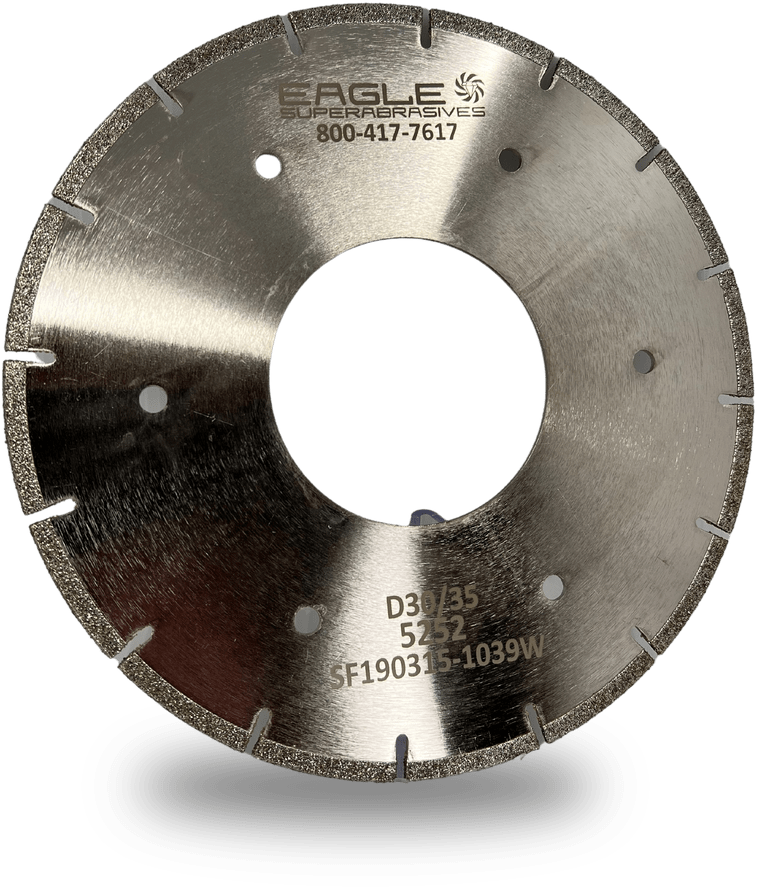

Electroplated

Very aggressive stock removal due to an extremely high concentration of abrasive particles that coat the entire grinding area of the wheel and abrasive grit exposure. Electroplated grinding wheels do not require dressing or sticking open, and never load up like a resin bond wheel. This is essential for optimal grinding.

Electroplated Bond Benefits

Electroplated wheels offer many advantages over other types of grinding wheels:

- Electroplated bonds hold their profile for the life of the wheel. Perfect for intricate profile grinding.

- Our wheels are the most economical superabrasives you can buy.

- Eagle’s electroplated wheels are the product of choice for composite cutting and machining, foundry de-burring, profile grinding, medical tool manufacturing, electronics, and aerospace industries.

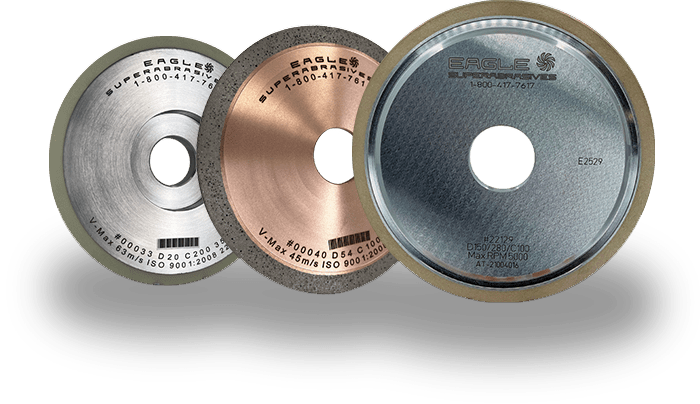

High Performance Wheels

When it comes to delivering top-quality grinding wheels, we don’t compromise. Eagle offers a wide range of abrasives, bonds, and core options. From start to finish, an application engineer will be by your side.

Advanced Technology

With our multilayer electroplated bond system, abrasive grains are attached to wheel cores with a very strong nickel coating that chemically and physically attaches the diamond or CBN to the wheel body.

Our wheels then have a secondary Nickel Matrix encapsulation layer creating a tighter bond for diamond and CBN particles. Customers on average, see a 34% increase in wheel life due to this secondary layer.

Plating peeling from the core is another common problem with other manufacturers plated wheels. The multi-stage Perma-Plate cleaning process we use during the manufacturing of a wheel guarantees you will not have problems with plating peeling from the core.

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.