Polyimide Bond

We offer two types of resin bond for diamond and CBN wheels: phenolic and polyimide resins. Depending on the demands of the application, however, polyimide bond wheels are made using a harder resin that can offer superior performance over phenolic resin bonds.

What is Polyimide Bond?

Polyimide bond grinding wheels are advanced and specialized tools designed for precision grinding applications, particularly in industries that demand high-performance solutions for challenging materials. The polyimide bond, a high-temperature-resistant polymer, serves as the matrix for holding abrasive particles, such as diamond or cubic boron nitride (CBN). The polyimide bond grinding wheels are known for their exceptional thermal stability, making them suitable for applications involving hard-to-machine materials that generate high levels of heat during the grinding process. Polyimide bond grinding wheels are commonly used in the manufacturing of semiconductor components, electronics, and other applications where heat-sensitive materials need precise shaping and finishing. The unique properties of polyimide bonds, including excellent chemical resistance and low thermal expansion, contribute to the longevity and efficiency of these grinding wheels, allowing them to deliver consistent performance in demanding and specialized grinding tasks.

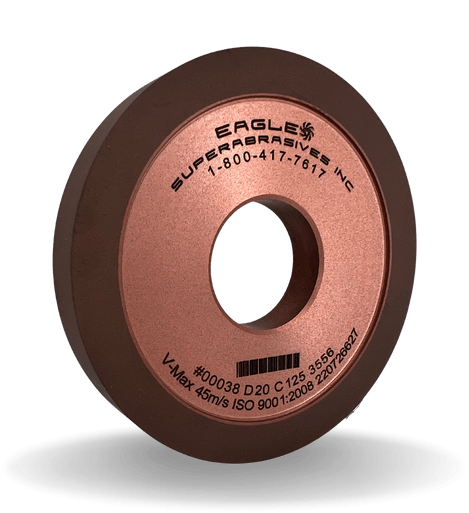

Polymide Bond Diamond & CBN Wheels

Polyimide is a resin made to withstand high temperatures. Though manufactured in the same way as a standard resin in many ways, the pressing temperature is about 3 times that of resin bond offering pressing forces up to 5 times more. Eagle’s polyimide resin bond grinding wheels offer maximum grinding performance and excellent holding power, making them the bond of choice for CNC grinders. Polyimide bonds also offer a lower power requirement. This results in the ability to achieve higher material removal rates. Wet dressing is typically recommended.

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.