Surface Grinding

Surface Grinding Wheels

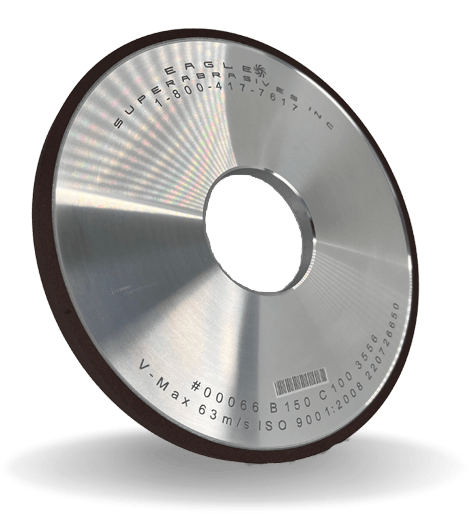

Surface grinding wheels are essential tools in metalworking and manufacturing, designed for precision surface grinding applications. Comprising abrasive grains bonded together with a resin or metal bond, these wheels are engineered to efficiently remove material from the surface of workpieces. The diamond or cubic boron nitride (CBN) grains facilitate effective material removal and produce fine surface finishes. Surface grinding wheels come in various shapes, sizes, and compositions, allowing them to be tailored to specific tasks and materials. They are commonly used in the production of flat surfaces on metals, ceramics, and other materials, ensuring tight tolerances and smooth finishes. Whether in automotive, aerospace, or general machining industries, surface grinding wheels play a crucial role in achieving the desired precision and quality in the final workpiece.

Speak to one of our engineers to get a surface grinding wheel designed for your specific application.

Eagle’s Benefits

A surface grinding wheel from Eagle Superabrasives is a universal choice when working with difficult to grind materials that need rapid stock removal and precise tolerance.

Worried that a stock wheel won’t cut it for your application? No worries! We manufacture custom wheels daily, and some of these wheels can ship in as little as seven days.

Surface Grinding Styles

As with any workplace and the operation involved, different grinding techniques are needed to achieve optimal results.

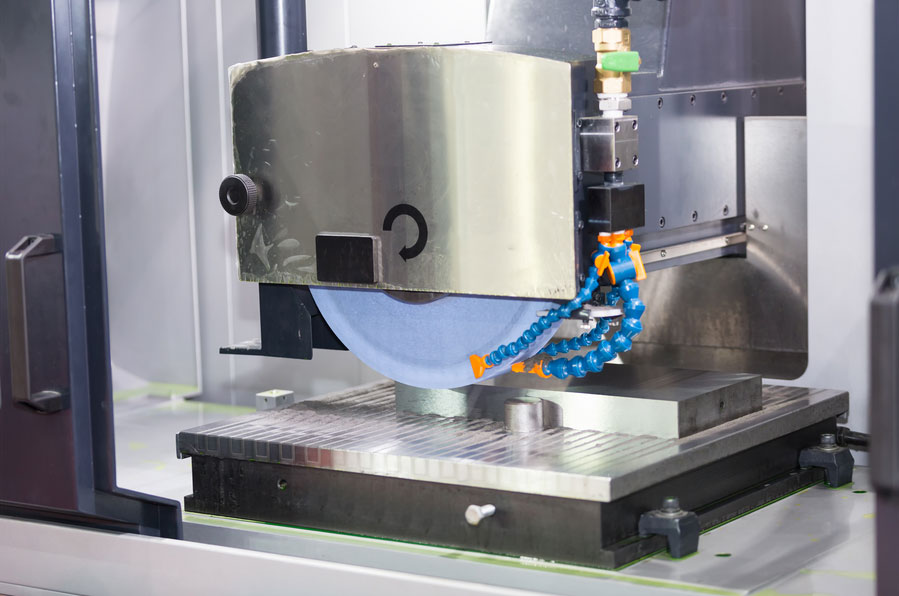

A surface grinding wheel can be used in two different ways for grinding.

Horizontal surface grinding – This style grinds by placing the edge of the surface grinding wheel so that it is in contact with the workpiece. Horizontal grinders are typically used for high-precision work on simple flat surfaces, tapers, or angled surfaces.

Vertical surface grinding – The face of the surface grinding wheel (segment, cylinder, or cup) does the grinding. The workpiece typically sits on a rotary table allowing for an even grinding finish.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898