PCD/PCBN

Eagle’s PCD / PCBN

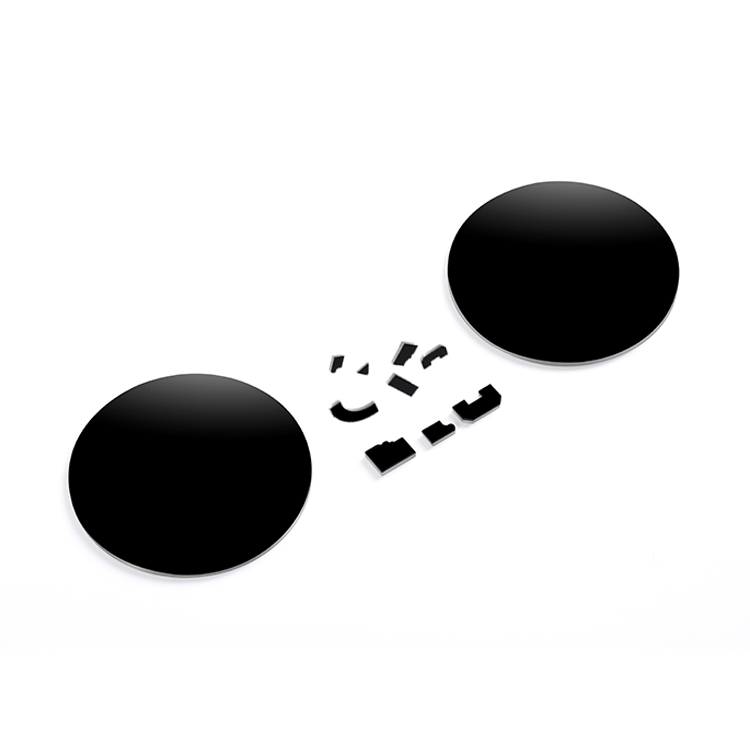

PCD and PCBN blanks and compacts work great in a broad range of milling, turning and machining applications.

Differences in PCD & PCBN Cutters

What are PCD Pucks?

Polycrystalline Diamond (PCD) is an advanced material known for its exceptional hardness and wear resistance, making it a preferred choice in cutting tools for machining non-ferrous metals, composites, and abrasive materials. Our PCD pucks stand out with superior durability, ensuring prolonged tool life and reduced downtime. Precision-engineered to perfection, our PCD pucks deliver unrivaled performance in demanding applications such as aerospace, automotive, and woodworking. With high thermal conductivity and excellent chemical stability, our PCD solutions provide optimal heat dissipation and maintain sharp cutting edges, resulting in impeccable surface finishes and enhanced productivity. Elevate your machining capabilities with our cutting-edge PCD pucks, setting new standards in efficiency and reliability.

What are PCBN Pucks?

Polycrystalline Cubic Boron Nitride (PCBN) is an essential material used in high performance cutting tool manufacturing , renowned for its exceptional hardness and heat resistance. Our PCBN pucks are meticulously crafted to meet the demands of high-speed machining applications, particularly in ferrous metal processing like hardened steels and cast irons. Featuring superior wear resistance and thermal stability, our PCBN pucks ensure prolonged tool life and consistent performance under extreme conditions. Precision-engineered with cutting-edge technology, our PCBN solutions empower industries such as automotive, aerospace, and gear manufacturing to achieve unparalleled efficiency and accuracy. Choose our PCBN pucks for a transformative edge in precision machining and reliable, long-lasting tooling solutions.

Both PCD and PCBN show excellent wear characteristics and offer unparalleled performance in terms of thermal hardiness, toughness and stability over the life of the toughest projects.

In Need of Compacts?

For your custom PCD & PCBN compact needs, we offer same-day shipments to participants of our inventory program with no minimum stocking requirements in most cases.

Eager to learn more about our PCD and PCBN products? Looking to make a change in your overall production and bottom-line?

Contact your Eagle representative today to discover solutions tailor-made to meet the demands of your toughest jobs.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898