Metal Bond

Metal bond grinding wheels are robust and highly durable tools used in precision grinding applications across various industries. Metal bond grinding wheels are composed of metallic particles, typically bronze, sintered together with a mixture of diamond or cubic boron nitride (CBN) abrasive grains. The metal bond provides excellent stability and strength to the grinding wheel, making it suitable for demanding tasks that require high material removal rates and precision surface finishes. Metal bond grinding wheels are known for their long lifespan and resistance to wear, making them ideal for applications involving hard and difficult-to-machine materials such as carbide, glass, ceramics, and composites. These wheels are widely used in the manufacturing of cutting tools, aerospace components, automotive parts, and other applications where precise and efficient grinding is crucial for achieving optimal results.

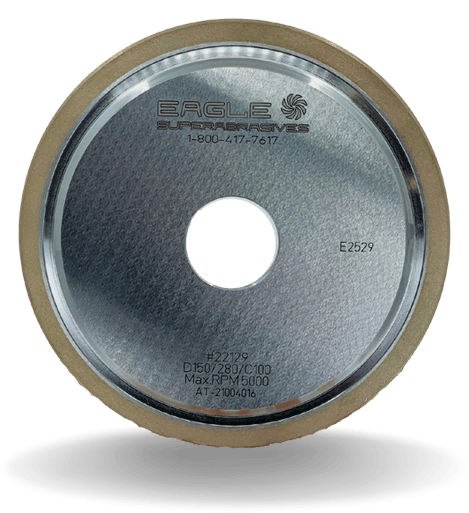

Metal Bond Diamond & CBN Wheels

In high demand grinding operations, metal bond diamond and CBN wheels are the most durable and consistent abrasive solution. Exemplifying long tool life and low maintenance, the metal bonds in our MultiTec wheels are ideal for their extreme abrasion resistance.

Metal bond grinding wheels are ideal for grinding glass, certain composites, and some metals. Metal bonds are built for endurance and form-holding performance. Using a metal bond helps to enhance life and form holding of the wheel. By applying CBN or diamond powders to the metal bond, you’ll enjoy a product that holds its shape longer than any other bond system during use. Metal bond grinding wheels hold the superabrasive grain so strongly, that they last longer than any other bond type.

MultiTec Solution

The primary qualities of metal bonded wheels are endurance and performance. Selecting a metal bonded wheel is most important when used for operations involving form and plunge grinding, as well as grinding single-edged tools because of the exceptional abrasion, impact and wear resistance, resulting in maximum productivity per project.

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.