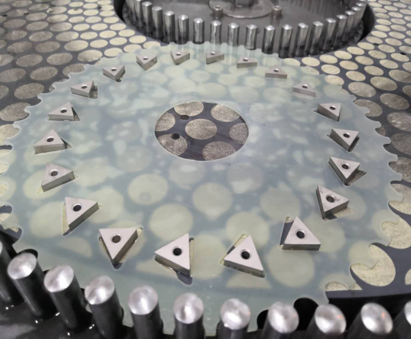

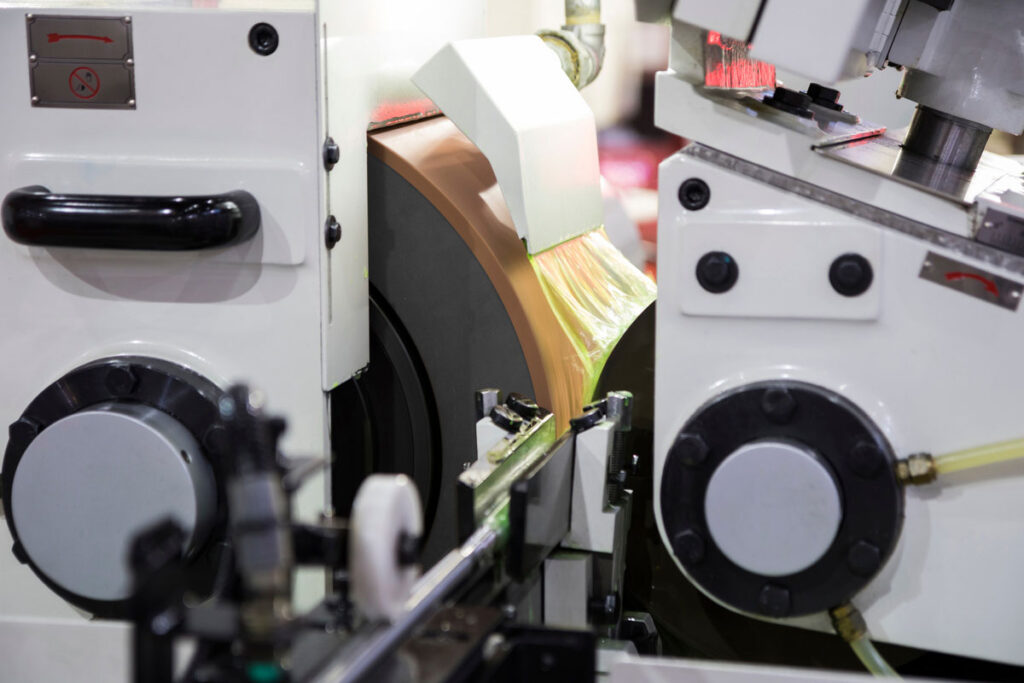

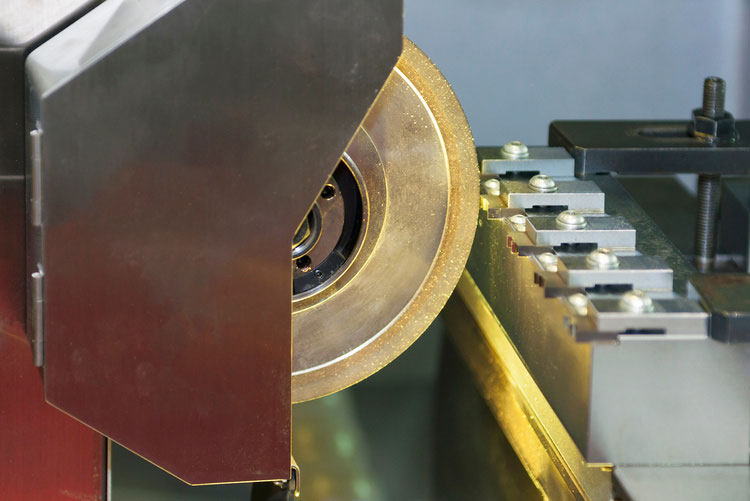

Whether you’re looking for a metal bond to cut glass, or a tougher wheel to cut through difficult-to-grind materials, our extensive inventory of 6,000 grinding wheels will be sure to meet your needs.

Applications

Worried that a stock wheel won’t cut it for your application? No worries! We manufacture custom wheels daily, and some of these wheels can ship in as little as seven days.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

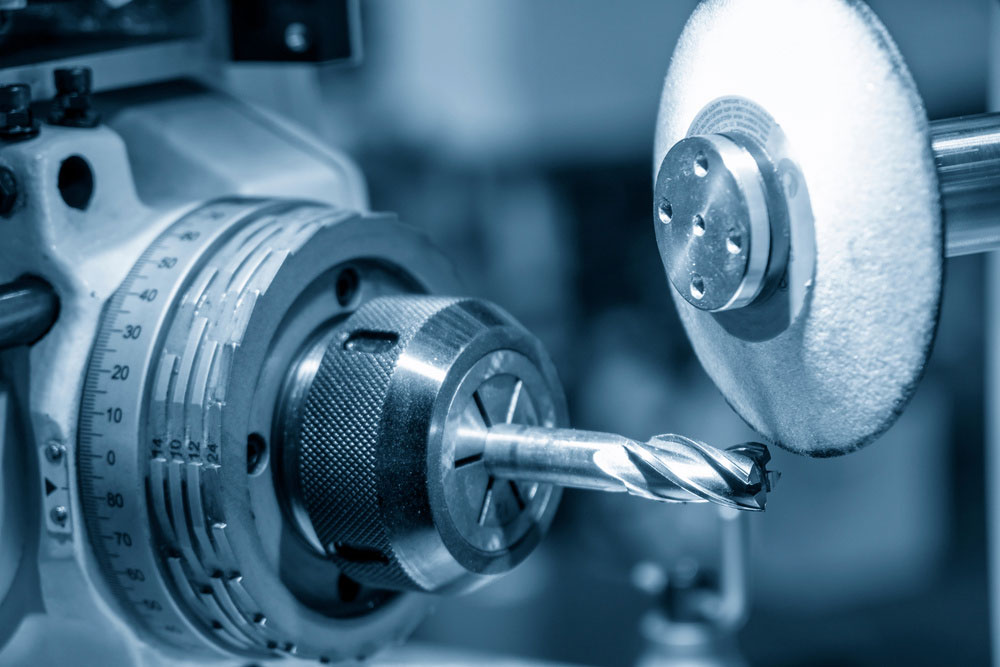

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898