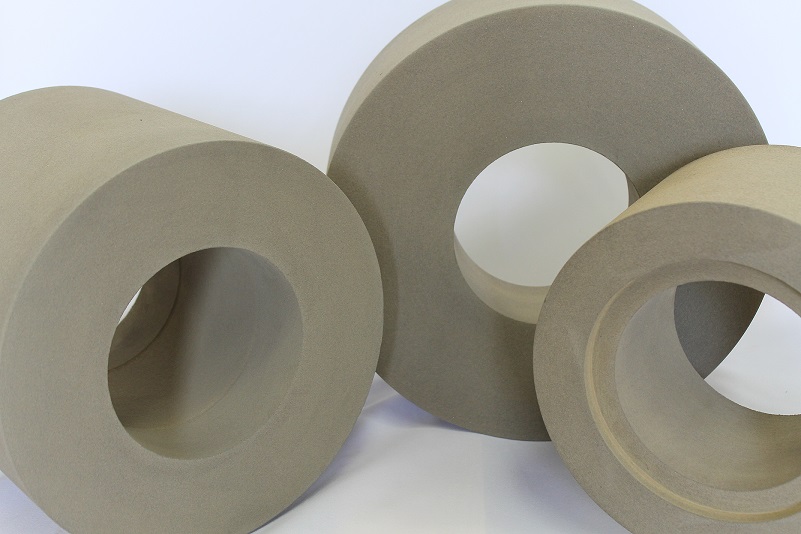

Regulating Wheels

Eagle’s HyperGrip Rubber Matrix Technology delivers the ultimate holding power. Our regulating wheels are manufactured to the highest tolerances using a 100% natural rubber bond matrix. The matrix holds the abrasive grain in place and provides consistent abrasive exposure. These wheels provide excellent grip allowing for high stock removal and a consistent rotation of the workpiece.

Rubber Bonded Regulating Wheels (also called Control or Feed Wheels) are manufactured by the rubber calendaring process for optimum performance.

Applications

Centerless grinding & polishing of:

- Bars

- Tubes

- Fasteners

- Bearings

- Rotors

- Valves

- Balls

- Needles

- Medical Wires, etc.

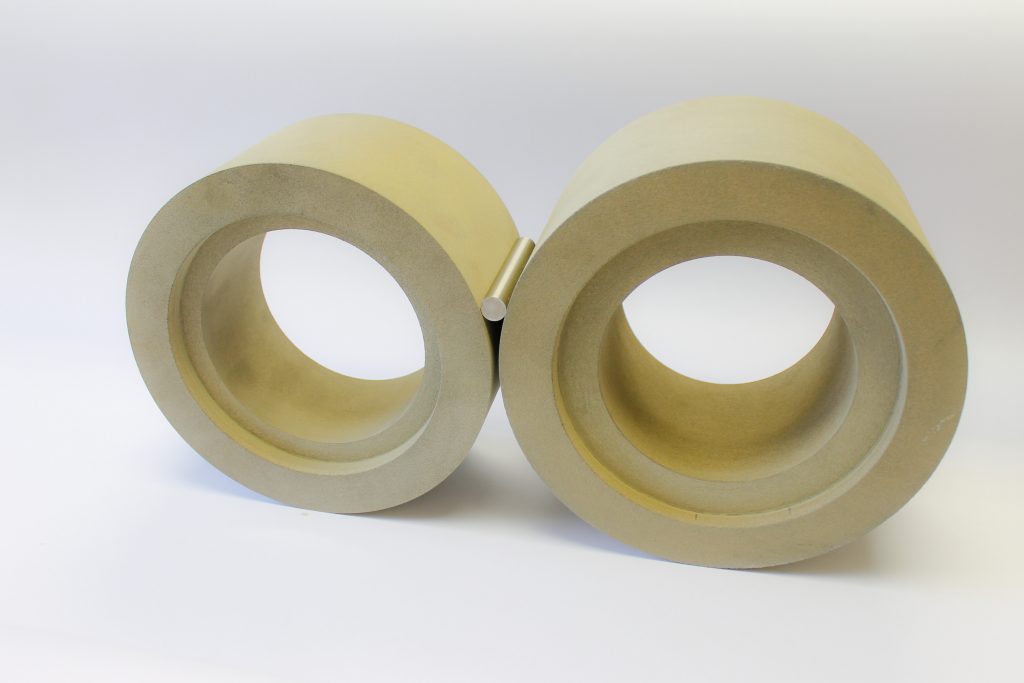

Sizes

- Complete range of standard sizes manufactured

- Non-standard (e.g. slotted) & special sizes routinely manufactured

- Wheels with steel cores for Glebar & Royal Master machines available.

- Wheels manufactured for special grinding operations

- Wheels recessed as required

Specifications

Specifications available for infeed, end-feed & through-feed applications

Complete range of specifications including standard specifications with abrasive grit sizes (80, 120 and 180)

Tailored to suit particular needs & applications

Machine Types

- Koyo

- Churchill

- Ghiringhelli

- Glebar

- Royal Master

- Cincinnati

- Lidkoping

- Estarta, etc.

Common sizes

- 9″ x 4″ x 4″ Bore A80

- 12″ x 2″ x Bore A80

- 12″ x 4″ x Bore A80

- 12″ x 6″ x Bore A80

- 12″ x 8″ x Bore A80

- 12″ x 10″ x Bore A80

- 14″ x 6″ x Bore A80

- 14″ x 8″ x Bore A80

- 14″ x 10″ x Bore A80

- 14″ x 20″ x Bore A80

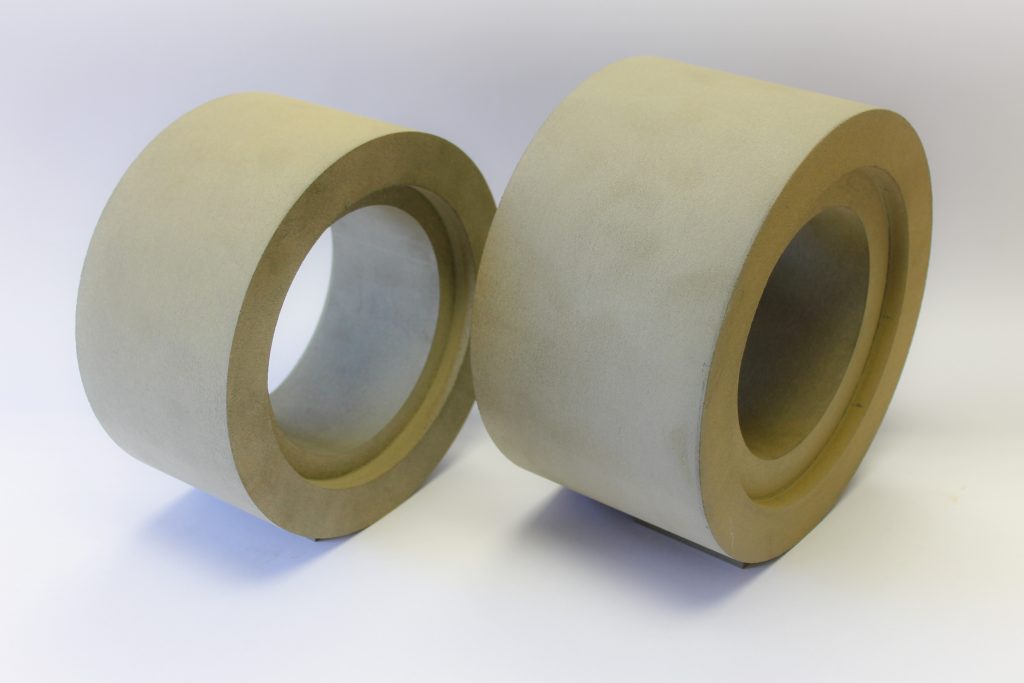

A crucial component when centerless grinding

The regulating wheel serves as a crucial component when centerless grinding. One of its key assets is its ability to regulate the rotational speed and feed rate of the workpiece. By doing so, it ensures uniform material removal and dimensional consistency, essential for producing consistent, high-quality components.

Moreover, the regulating wheel acts as a stabilizing force, minimizing vibration and deflection during grinding operations. This stability is essential for achieving the desired surface finish and dimensional accuracy of the workpiece

In essence, the regulating wheel is equally important as the centerless wheel, providing such as precision control, stability, and optimal contact, making it an essential part of the grinding process.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898