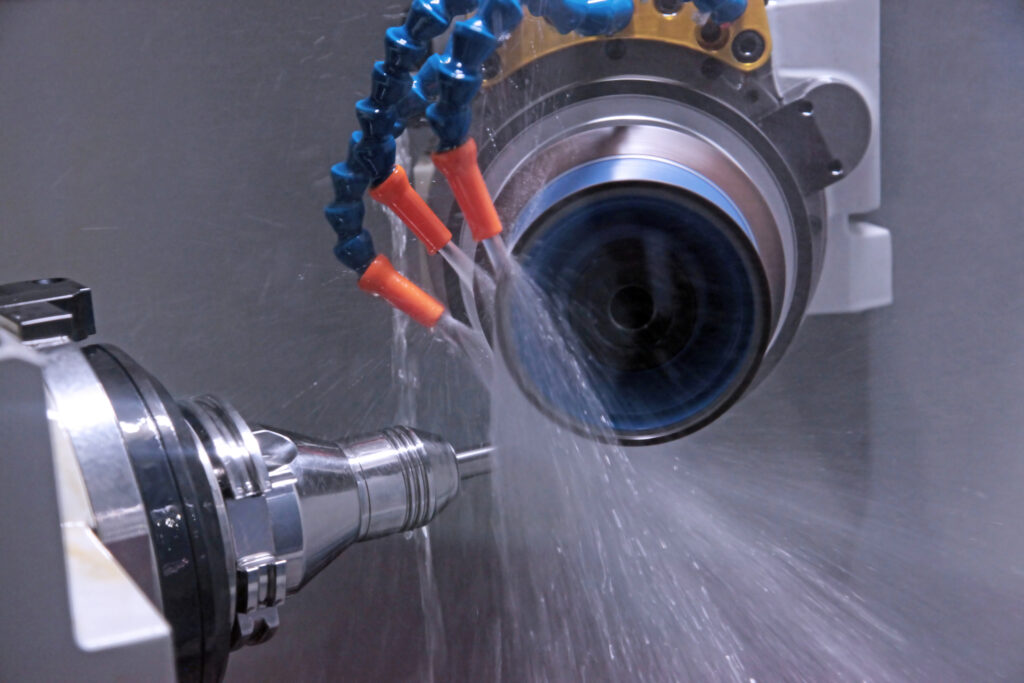

Coolant for Diamond and CBN Wheels

GrindClean GK05 LF Water-soluble synthetic grinding coolant is for companies grinding carbide or steel. GK05 LF coolant is a concentrated high-performance coolant with additives designed to dramatically reduce cobalt leaching in the machining and grinding of tungsten carbide. If you have problems with your coolant turning pink due to cobalt leaching, then you should try GK05 LF.

GK05 LF is an oil-free coolant that provides fast swarf removal, exceptional rust protection, and high cooling. Even when heavily diluted with water, it still provides excellent protection to freshly machined and ground surfaces. GK05 LF protects both machines and working parts against build-up of sticky residue associated with the grinding process, and contains ingredients that won’t attack aluminum fixtures. The coolant has a high cleaning action that removes grinding fines thereby minimizing wheel loading. GK05 LF is a low foaming coolant that can be used with recycling or centrifuge systems.

GK05 LF is already in use by many leading carbide and HSS tool manufacturers throughout North America. When used in conjunction with a central coolant system, GrindClean GK05 LF will increase diamond/CBN grinding wheel life and enable the wheel to produce a high-quality finish. The result is reduced grinding wheel costs and increased customer satisfaction with the finished product.

Benefits of GK05 LF include:

- Outperforms other coolants in reducing cobalt leaching when grinding carbide

- Exceptional rust protection

- No build-up of sticky residue

- No foaming or suds

- Will not attack or pit aluminum

- Quickly separates and settles carbide fines, does not allow fines to remain in suspension

- Long shelf life (GK05 LF comes premixed, no need to add powders or solids)

- Special additives to prevent bacterial growth

- Low odor, easy to mix

- Increased diamond/CBN wheel life

- Reduced wheel loading

- Improved workpiece surface finish

Coolant Information

Dilution Ratio

The ideal range is 20:1 (5% coolant, 95% water) to 10:1 (10% coolant, 90% water). Start out with a ratio of 20:1 for initial tank fills. Use clean, soft water if possible. If you have very hard water with lots of minerals, then increase the percentage of coolant to 15:1 or 10:1

Topping off coolant

Due to the evaporation of water in the coolant mixture, you should not top off the tank at the same dilution ratio that was used to fill the tank with fresh coolant. A good rule of thumb is to use one-half of the amount of coolant when topping up. If you start a fresh batch of coolant at a ratio of 20:1, then top off with a ratio of 40:1 (Brix reading of 0.5).

When to change Coolant

Coolant that is maintained at the correct dilution ratio and properly filtered by a centrifuge and/or filter type cartridge/paper should last up to 12 months. Note the translucent green color of a fresh batch of coolant. Unlike other brands of coolant, properly maintained coolant will keep its original color even after 6 months of use.

Grinders that have a small coolant tank (e.g., 20-gallon tank with inexpensive paper filter) will need to have their coolant changed more frequently (e.g., every 60 days), especially if grinding soils are continually re-circulated through the pump due to poor filtration.

In general, coolant life will depend upon how well you filter the coolant, the quality of your water, and how well you maintain the dilution ratio and volume of coolant in the tank.

Calculating the amount

of coolant to add for initial fills

First, calculate the volume (cubic ft) of your tank. Next, multiply the total by ft³ by 7.5 to convert to gallons. Then divide the total gallons by the dilution ratio to obtain the total amount of coolant to add.

For example:

Tank width = 2 ft, Length = 3 ft, Depth = 1 ft. Total cubic feet: 2’x3’x1′ = 6 ft³

Total gallons = 6×7.5 – 45. Dilution ratio – 20:1. Amount of coolant to add = 45 / 20 = 2.25 gallons

Time to get into the 21st century

Today’s grinding machines grind 2,3 and even 4 times faster than 10 years ago. Grinding wheel performance has been keeping up with technology with new high-temperature bonds and core designs. But until recently when it came to coolants you were faced with the same choices.

We have changed all that.

With coolant pressures now reaching in excess of 600 psi, the demand for high-performance specialized coolant programs has never been more intense. That’s why you need to turn to grinding Lubricants for real performance and productivity.

Oil Based Coolant

Oil grinding fluid/coolant. Oil coolant is a light viscosity, mineral-based oil designed for grinding or cutting steel, carbide, quartz, and crystal. Oil coolant is ideal where a high lubricity, low viscosity cutting or grinding oil is required. Oil coolant also finds use in honing and finishing of surgical knives and other products that require a very fine finish. The high flash point and non-toxic, biodegradable components of oil coolant make it safe to use.

Oil coolant is used by many leading carbide and HSS tool manufacturers throughout North America. It can be used on most types of saw, tool, and rotary grinders. Oil coolant grinding coolant will increase both the grinding wheel and grinding machine life. In addition, the resulting surface finish will be better than grinding with water-based coolants. The major advantages of Oil coolant are reduced grinding wheel costs, reduced grinder maintenance costs, and increased customer satisfaction with the finished product.

Benefits of oil coolant include:

- Increased machine life, less grinder maintenance compared to water-based coolant

- Improved workpiece surface finish

- Increased diamond/CBN wheel life

- Excellent corrosion/rust protection

- Excellent lubricity

- Can filter below 1 micron without removing additives

- No foaming or suds

- No cobalt leaching when grinding carbide

- No problems with bacterial growth

- Very mild odor, translucent light brown color

Oil coolant has a long service life if filtered properly. It has a minimum flash point of 320º F and a specific gravity of 0.90. An air cleaning system (e.g., SMOG-HOG) for collecting coolant mist is recommended for grinders without a full enclosure. All CNC automatic grinders running oil-based coolants must have a spark arrester installed (check with grinder manufacturer for more details).

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898