Truing Your Diamond and CBN Wheels

- Examine wheel flanges and spindle with care, and make sure flange surfaces are flat, clean, smooth, and contain no damage.

- Check your machine spindle for run-out. Ensure it is less than 0.0002”.

- Mount your wheel.

- Mark edge being trued with a sharpie marker if desired. The wheel is not true until all marker is removed.

- Using a brake truing device or brake dresser:

- Start the diamond wheel at normal RPMs.

- Tap the brake dresser wheel so that it is spinning with the diamond wheel.

- Bring the 2 wheels together until they touch. Make sure the truing wheel is spinning when contact is made.

- Traverse the truing wheel back and forth at a comfortable speed.

- In-feed should not exceed 0.0005”/pass.

- Continue until wheel is true.

- Marker will be removed. If any still shows, this is a low spot in the wheel and the wheel is not true.

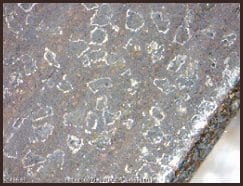

Dressing Your Diamond and CBN Wheels

- Select a dressing stick one or two grit sizes finer than the abrasive in the diamond or CBN wheel.

- We recommend a soft silicon carbide or aluminum oxide dressing stick a few steps finer to “open up” the wheel again.

- Sticks that are too hard or too coarse can wear away too much of the wheel’s bond, shortening the overall life of your wheel.

- Turn off the coolant pump.

- Turn on the machine and allow the grinding wheel to reach full RPM.

- Turn off the spindle motor.

- Apply the dressing stick to the abrasive section on the wheel with light to medium pressure until the wheel stops rotating.

- Repeat the above step until the dressing stick feels like it is being pulled or drawn into the wheel.

- Depending on the condition of the wheel surface, this step may need to be repeated up to four or five times to really expose more cutting particles and return the wheel to its aggressive nature.

- Warning: Do not use cluster or single-point diamond dressing tools for truing or dressing diamond or CBN wheels.