Diamond and CBN Wheels are currently fighting for the spotlight in the grinding industry.

With an industry that mostly relied on Diamond, as the superabrasive choice for grinding difficult to grind (DTG) materials, CBN has quickly become a rival of diamond.

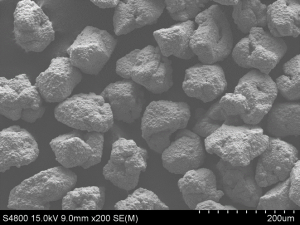

Diamond is the hardest material known to man, but chemist have created a man-made material that rivals the strength of diamond, which has become known as CBN.

Diamond and CBN have the same crystal structure, with diamond consisting of pure carbon, whilst CBN is made up of the elements boron and nitrogen.

Why Choose Diamond Wheels?

Diamond is widely known as being the hardest material for grinding and sharpening.

It is cost effective when working with carbide, glass, ceramics, ferrite and non-ferrous metals.

The biggest advantage of using a diamond wheel is its hardness and also its high thermal conductivity. The high thermal conductivity, allows the diamond crystals to transfer heat away from the cutting edge of the wheel and, when necessary, dissipate the thermal energy through the bond and grinding wheel body.

Our Diamond Wheels are particularly suitable for working with all grades of carbides, hard faced alloys, sapphire glass, graphite and many other materials.

Why Choose CBN Wheels?

CBN stands for cubic boron nitride, a superabrasive that offers almost the hardness of diamond, cool cutting and the ability to work with ferrous materials, unlike diamond.

Diamond is composed of pure carbon and is produced under high heat and pressure. When Diamond is used to grind hardened steel it causes a chemical reaction and essentially begins to form graphite and lose it strength.

So what makes CBN better for working with hardened steels? CBN is not composed of carbon atoms, instead it is formed with boron and nitride under pressure and heat. Grinding hardened steels produces high temperatures, CBN has a great thermal conductivity, keeping it cool under extreme heat.

Our CBN Wheels are better suited for machining hardened steels, high speed steels, stellite and nickel based alloys and tool steels.

Trust the experts

There are a number of advantages of implementing either a diamond or cbn wheel into the workplace. It is important to know which wheel is best for the material that you will be working with to ensure that you are getting the most productivity out of the wheel.

Each will increase your productivity rate as well as save you money in the long run due to fewer wheel changes and less breakdown of the superabrasive material.

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We pride ourselves in offering the best grinding wheels as well as the best customer service to truly enhance your purchasing experience. Our friendly staff, will provide advice and support along the way, answering any questions that may arise. Contact us today!