With a wide choice of products offered by major grinding wheel manufacturers, selecting a grinding wheel for your business and project can be a challenge. Depending on the geometry and type of the material you are grinding, factors to consider include the type of abrasive, bond hardness of the wheel, and grit size. As proper wheel selection ensures that the required finished product quality is achieved, here is a brief guide to help you make an informed choice.

4 Tips for Selecting the Right Diamond Wheels for Manufacturing

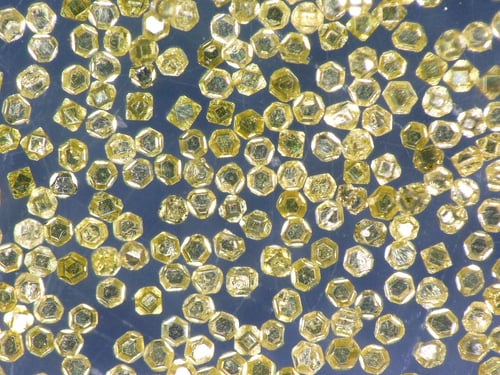

Depending on the material being cut, there are three types of diamond abrasives commonly used: natural, synthetic, and metal-coated synthetic diamond. Although natural diamond is rarely used nowadays due to its high cost, it is an excellent choice for grinding glass, ceramic, composites, and carbide. Synthetic diamond, on the other hand, is typically used for grinding non-ferrous metals and is commonly used in finish and critical form applications like valves, cranks, and automotive cam grinding. The third type, metal-coated synthetic diamond, is also used for cutting non-ferrous metals. This type of diamond is created by coating the grain with nickel to enhance its grain-holding power and heat resistance.

In general, diamond abrasives offer excellent wear resistance and grit retention, making them suitable for semi-finish and rough processing of challenging-to-machine materials. These materials include stone, fireproof and semiconductor electronic materials, ferrite, ceramics, and glass. Additionally, diamond abrasives are commonly used for materials such as quartz, silicon, crystal, titanium alloys, and cemented carbide.

2. Choosing the Right Type of Bond

The bonding material used in grinding wheels is crucial for holding the abrasive grains together. There are four main bond options: electroplated, vitrified, resin, and metal. Resin bond diamond wheels have a wide range of applications, including centerless, off-hand, and both dry and wet grinding. They are particularly effective for cutting ceramics, cermet, carbide, semiconductors, ferrites, and glass.

On the other hand, metal bonds are commonly used for materials that are hard and brittle, such as sapphire, ceramics, glass, tile, and quartz. These grinding wheels are specifically designed for cutting highly abrasive materials and have a long lifespan.

Vitrified bonds are used for grinding ceramics, PCBN, and PCD tools. Vitrified diamond wheels are also ideal for fragile and tough materials such as silicon, sapphire, and heat-treated HSS materials. As a rule, vitrified and metal bonds are custom-ordered and more expensive.

The fourth variety, electroplated bonds are best for low abrasive grinding and form grinding of heat-resistant materials and ferrous automotive parts.

3. Choosing the Concentration?

The concentration of diamond in a diamond grinding wheel plays a pivotal role in determining its suitability for various applications. For instance, a C75 concentration, with 75% diamond grit, is typically well-suited for dry grinding tasks. The relatively lower concentration allows for efficient heat dissipation during dry grinding, preventing the diamond from overheating and losing its cutting effectiveness. This makes C75 ideal for applications where keeping the workpiece cool is crucial.

On the other hand, C100 concentration, with 100% diamond grit, is a versatile choice for general grinding on materials like carbide. Its balanced composition provides an excellent compromise between abrasive power and heat management, ensuring efficient stock removal while maintaining the diamond's longevity. Lastly, C125 concentration, with an even higher proportion of diamond grit, is reserved for high-production scenarios where aggressive cutting and maximum durability are essential. In such applications, like heavy-duty metalworking, C125 ensures extended wheel life and superior performance, making it an indispensable choice for industries requiring high-volume grinding

4. Look at the Grit Size

Grit size indicates the number of the smallest openings through which the abrasive grain will pass. For instance, a 50-grit-sized grain will pass through a sieve with 50 holes per inch.

Grains are generally divided into very fine (320 – 1,000), fine (320 – 240 ), medium (240 – 150), and course (150 – 60 ). Course sizes are used for snagging and billet conditioning in foundries and steel mills. Medium sizes are best suited for high stock removal and surface finishing. Fine-grain sizes are used for small-diameter and fine-finish grinding while very fine grits are best for lapping and polishing.

Summing Up

When choosing a diamond grinding wheel for manufacturing, the main factors are the type of abrasive and bond, the grade of the wheel, and the grit size based on the material you are grinding. Other factors that affect choice include the wheel speed in operation, the amount of stock that needs to be removed, and grinding contact between the work material and the wheel. As each factor matters, taking all factors into account is the best way to optimize grinding performance.

Whether you are looking for general guidance or are ready to get a quote, we are dedicated to helping you find the right solution – and if we can’t provide the exact wheel you need, we will let you know. We hope you’ll explore the ways our team can help your business stay ahead of the competition.

Subscribe to email updates

Subscribe to our blog to get the latest updates from the experts on Grinding Wheels! You can easily unsubscribe at any time